|

|

| |

| |

|

|

|

|

|

BAMBOO

FLOORING COLORATION AND CONSTRUCTION |

| |

|

|

|

|

|

|

What is the difference between Naturalized and

Carbonized Bamboo? |

| Bamboo

flooring is typically available in two colors, natural and carbonized.

Additionally, other colors in bamboo flooring may be obtained by staining

the unfinished product. The natural color is yellow/blonde whereas the

carbonized color has a darker, coffee-colored tone. Generally, carbonized

flooring is not recommended for certain high traffic commercial applications

since the steam-treatment process weakens the bamboo strips by about 20%.

However, our manufacturing process differs from most other manufactures in

that the initial bamboo strip processing is within a major bamboo growing

area. Because of this, our manufacturers are able to immediately cut and

strip the bamboo shoots and, within 2 hours, carbonize these strips.

Consequently, we gain an 8% hardness in these strips by eliminating the

boiling water treatment normally required when processing bamboo.

|

| |

|

|

|

|

|

|

Naturalized |

|

Carbonized |

|

| |

|

|

|

|

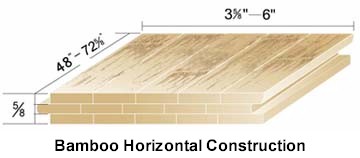

| What is the

difference between horizontal and vertical bamboo flooring? |

| Bamboo flooring has

two basic constructions; horizontal and vertical. Horizontal boards are

manufactured by laminating three layers of bamboo strips side-by-side. This

presents an appearance that has been compared to flattened bamboo stalks,

with the unique nodal pattern characteristic of bamboo. |

|

| |

|

|

|

|

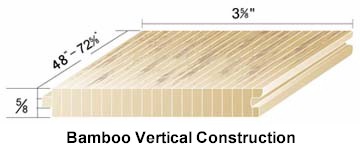

| The vertical

construction is produced by turning the bamboo strips 90 degrees and

positioning them next to each other. The strips are then pressed into a

single layer. In effect, one walks on the edge of the strip. The horizontal

construction, when properly assembled, is both harder and more dimensionally

stable than the vertical construction. |

|

| |

|

|

|

|

|

|

|

|